- News & Events

- Blog

- Follow us

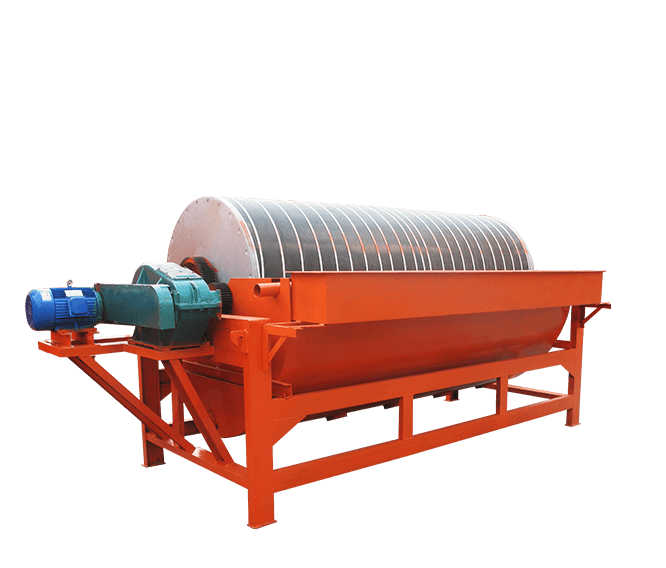

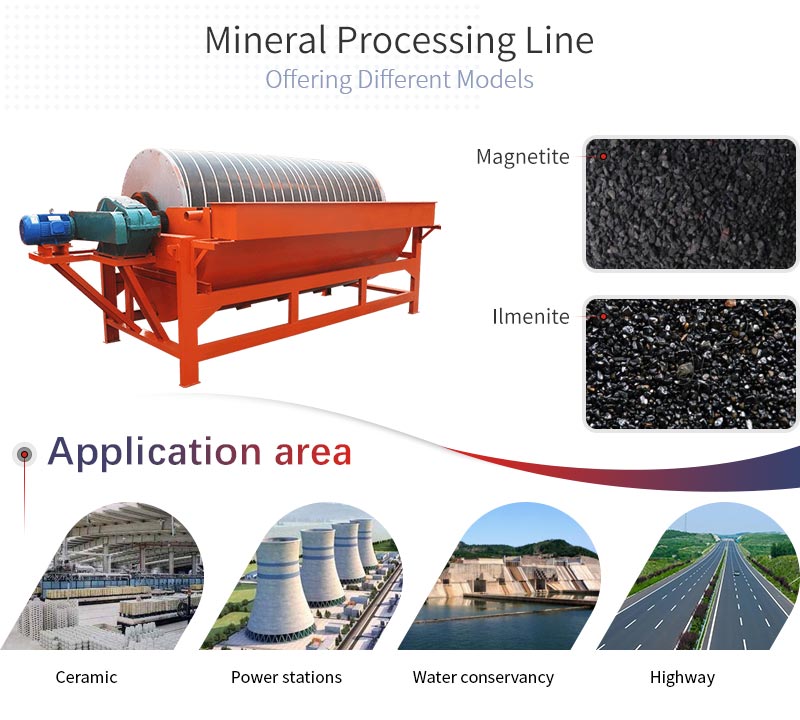

Application fields: wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3 mm or less.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

The magnetic separator is applied to conduct the wet-type magnetic separation to process magnetite, pyrrhotite, calcined ore, ilmenite, etc. It can also be used to remove iron from some materials, such as coal, non-metal ores, building materials. The magnetic separator’s magnetic system is made from excellent ferrite or the combination of it and rare earth magnetic steel. The average magnetic induction of the drum surface is 100-600mT. The magnetic separator, made by Hongxing, has many advantages, such as simple structure, big handling capacity, etc.

High magnetic intensity, good magnetic field performance.

Low energy consumption, high processing capacity.

Wide range of applications, high-quality products.

Reasonable structure & good stability, hot sale around the world.

According to magnet type, it can be divided into the permanent magnetic separator and the electromagnetic iron remover.

By the mineral processing methods, it can be divided into the dry-type iron remover and the wet-type iron remover.

By different magnetic systems, there are the drum-type magnetic separator, and the drum roller-type one.

Due to the differences in structure, there are the single-drum magnetic separator, double-type one, and the multi-drum one. There are also some other kinds of classification methods of it.

| Model | Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

| Model | Feeding size (mm) |

Processing capacity (t/h) |

| CTB6012 | 2-0 | 10-20 |

| CTB6018 | 2-0 | 15-30 |

| CTB7518 | 2-0 | 20-45 |

| CTB9018 | 3-0 | 40-60 |

| CTB9021 | 3-0 | 45-60 |

| CTB9024 | 3-0 | 45-70 |

| CTB1018 | 3-0 | 50-75 |

| CTB1021 | 3-0 | 50-100 |

| CTB1024 | 3-0 | 60-120 |

| CTB1218 | 3-0 | 80-140 |

| CTB1224 | 3-0 | 85-180 |

| CTB1230 | 3-0 | 100-180 |

| CTB1530 | 3-0 | 170-280 |

For customization, please contact us.

Magnetite, pyrrhotite, calcined ore, ilmenite, etc.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene