- News & Events

- Blog

- Follow us

Application range: mining, ore dressing, building material, metallurgy, chemical engineering, etc.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

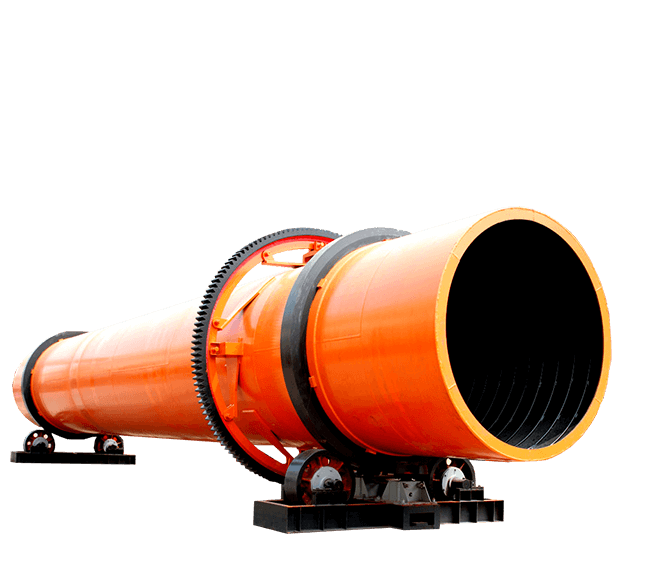

The drum dryer also named drying machine, is mainly used to dry the materials with certain humidity in many industries, such as ore dressing, building, metallurgy, chemical engineering, and so on. With high adaptability, the drum dryer can be used to dry a variety of materials.

The drum dryer, made by Hongxing, adopts the new-type lifting plate, which can make the material scatter evenly.

The drum dryer has reasonable specifications, which has been widely used in cement plants and ore dressing plants.

The drum dryer has strong adaptability to materials, simple and reliable operation, high yield and durability.

New internal structure, more adaptable to moisture and viscosity of materials

The drum dryer, made by Hongxing, adopts the new-type lifting plate, which can make the material scatter evenly to form thin material curtain wall, which can make the material touch the hot air completely, to make full use of the thermal energy. Hongxing’s drum dryer has reasonable specifications, which has been widely used in cement plants and ore dressing plants.

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

| Spec./m (Dia.×Length) |

Capacity (t/h) |

Highest Inlet Air Temperature (℃) |

| Φ1.2×8.0 | 1.9~2.4 | 700~800 |

| Φ1.2×10 | 2.4~3.0 | 700~800 |

| Φ1.5×12 | 4.5~5.7 | 700~800 |

| Φ1.5×14 | 5.3~6.6 | 700~800 |

| Φ1.5×15 | 5.7~7.1 | 700~800 |

| Φ1.8×12 | 6.5~8.1 | 700~800 |

| Φ1.8×14 | 7.6~9.5 | 700~800 |

| Φ2.2×12 | 9.7~12.2 | 700~800 |

| Φ2.2×14 | 11.4~14.2 | 700~800 |

| Φ2.2×16 | 13.0~16.2 | 700~800 |

| Φ2.4×14 | 13.5~16.9 | 700~800 |

| Φ2.4×18 | 17.4~21.7 | 700~800 |

| Φ2.4×20 | 19.3~24.1 | 700~800 |

| Φ2.4×22 | 21.2~26.5 | 700~800 |

| Φ2.6×24 | 27.2~34.0 | 700~800 |

| Φ3.0×20 | 30.1~37.7 | 700~800 |

| Φ3.0×25 | 37.7~47.1 | 700~800 |

| Φ3.2×25 | 42.9~53.6 | 700~800 |

| Φ3.6×28 | 60.8~76.0 | 700~800 |

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Shell cubage (m³) |

Highest inlet air temperature (℃) |

| Φ1.5×15m | 20.27 | 850 |

| Φ1.5×17m | 22.97 | |

| Φ1.5×19m | 25.68 | |

| Φ1.8×21m | 35.91 | 850 |

| Φ1.8×23m | 39.33 | |

| Φ1.8×25m | 42.75 | |

| Φ2.2×21m | 58.10 | 850 |

| Φ2.2×23m | 63.61 | |

| Φ2.2×25m | 69.15 |

For customization, please contact us.

various metal ores, ore powder, coal powder, sand

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

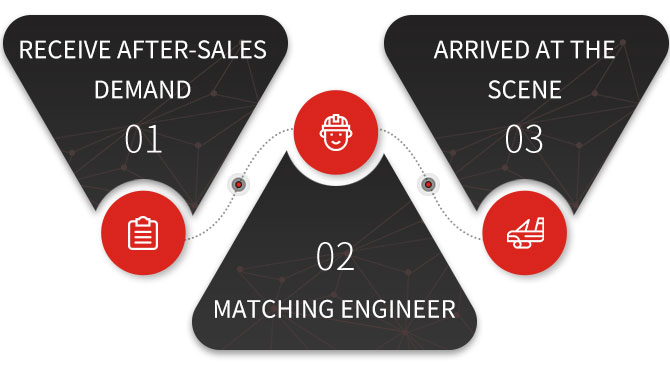

Receive after-sales demand

Matching engineer

02Arrived at the scene