- News & Events

- Blog

- Follow us

Application fields: cement, silicate, refractory, fertilizer, ferrous and non-ferrous metal beneficiation.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

Cooler is one of the important machines of the rotary kiln system and its functions are to cool the clinker from the rotary kiln from 1000-1300℃ to below 200℃ and to improve the quality and drinkability of the clinker.

The cooler feeding mouth adopts a KID system and pulsating air supply to quickly cool the high-temperature clinker from the kiln.

Increasing the strength and wear resistance of clinker and improving the operation rate of the equipment.

Through cylinder rotary drive adequately heat exchange, which cools the material to below 200℃, at the same time improve the quality of clinker and grinding

The air after cooling the material is all put into the kiln, which is used as the secondary circulating air, thereby reducing the labor intensity and increasing the output.

After nearly 40 years of industry experience, Hongxing mining machinery has absorbed the latest technology and concepts at home and abroad to develop products with an international advanced level. The Hongxing machine has formed its own unique and rich corporate culture.

our products have exported to more than 160 countries and regions around the world. However, we meet the customer's needs for the ultimate goal and promise 100% ex-factory price to save costs for customers. We have more products and industry information waiting for you to know, please leave a message or you can contact customer service for free online, or send an email to info@hxjq.com

| Spec./m (Dia×Length) |

Capacity (t/h) |

Installation Obliquity (%) |

Main Reducer |

Main Motor (kw) |

Weight (t) |

| Φ1.5×15 | 2~3 | 3~5 | ZQ500 | 15 | 28 |

| Φ1.5×20 | 3~4 | 3~5 | ZQ500 | 15 | 35 |

| Φ1.8×18 | 4~6 | 3~5 | ZQ500 | 18.5 | 47 |

| Φ2.0×22 | 7~8.5 | 3~5 | ZQ500 | 22 | 61 |

| Φ2.2×18 | 7~8.5 | 3~5 | ZQ500 | 22 | 64 |

| Φ2.2×22 | 8~10 | 3~5 | ZQ650 | 30 | 73 |

| Φ2.4×24 | 12~15 | 3~5 | ZS125 | 45 | 98 |

| Φ2.5×25 | 15~20 | 3~5 | ZS125 | 55 | 110 |

| Φ2.8×28 | 16~22 | 3~5 | ZL100 | 55 | 130 |

| Φ3.0×30 | 20~25 | 3~5 | ZL115 | 75 | 169 |

| Φ3.2×36 | 28~32 | 3~5 | ZL115 | 90 | 200 |

| Φ3.3×40 | 32~36 | 3~5 | ZI130 | 132 | 237 |

| Φ3.6×36 | 35~38 | 3~5 | ZSY450-28 | 185 | 318 |

| Φ4.0×36 | 50~60 | 3~5 | ZSY450-25 | 220 | 348 |

| Φ4.0×45 | 60~70 | 3~5 | ZSY450-25 | 250 | 414 |

| Φ4.5×50 | 70~75 | 3~5 | ZSY500-25 | 315 | 576 |

| Spec./m (Dia×Length) |

Capacity (t/h) |

Installation Obliquity (%) |

| Φ1.5×15 | 2~3 | 3~5 |

| Φ1.5×20 | 3~4 | 3~5 |

| Φ1.8×18 | 4~6 | 3~5 |

| Φ2.0×22 | 7~8.5 | 3~5 |

| Φ2.2×18 | 7~8.5 | 3~5 |

| Φ2.2×22 | 8~10 | 3~5 |

| Φ2.4×24 | 12~15 | 3~5 |

| Φ2.5×25 | 15~20 | 3~5 |

| Φ2.8×28 | 16~22 | 3~5 |

| Φ3.0×30 | 20~25 | 3~5 |

| Φ3.2×36 | 28~32 | 3~5 |

| Φ3.3×40 | 32~36 | 3~5 |

| Φ3.6×36 | 35~38 | 3~5 |

| Φ4.0×36 | 50~60 | 3~5 |

| Φ4.0×45 | 60~70 | 3~5 |

| Φ4.5×50 | 70~75 | 3~5 |

For customization, please contact us.

Limestone, cement clinker, bauxite, activated lime, aluminum hydroxide, kaolin, etc.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

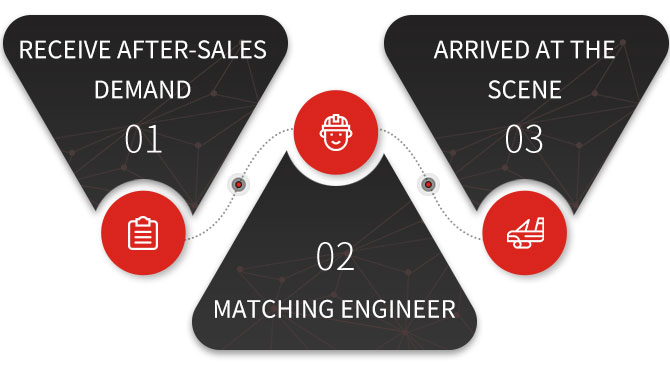

Receive after-sales demand

Matching engineer

02Arrived at the scene