- News & Events

- Blog

- Follow us

Made in China

Two weeks delivery, custom cycle, please consult

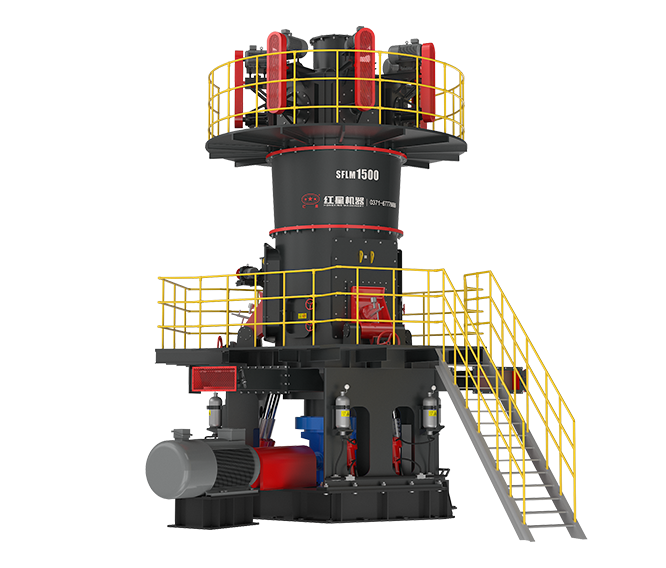

SFLM series ultra-fine vertical mill is a large-scale ultra-fine vertical mill equipment suitable for the development requirements of the non-metallic mineral industry,which is an ideal equipment for the large-scale production of ultra-fine powder with high efficiency,high output,environmental protection and energy saving. It is widely used in chemical industry,metallurgy,non-metallic minerals and other industries,and is suitable for ultrafine powder production and processing of limestone,calcite, marble,heavy calcium,pyrophyllite,talc and other minerals.

High grinding efficiency

Specially designed roller sleeve and liner grinding curve for ultra-fine powder grinding,it is easier to form a material layer,with high grinding efficiency and one-time grinding with high yield.

Highly efficient and energy-saving

Adopting the principle of variable frequency multi-head powder separator,the fineness of the ground finished product can be achieved within the selected range.It saves energy consumption by 30%-50%compared with ordinary mills.

Low operation and maintenance cost

The grinding roller can be turned out of the machine with a hydraulic device,making maintenance easy.The grinding roller and liners are made of high-quality materials,and the roller sleeve can be turned over to use,and the service life is long.

Stable product quality

Adopting the material layer grinding principle,the material stays in the mill for a short time,reducing repeated grinding.The finished product contains less iron,the whiteness and clarity are high,the product particle shape is uniform,the particle size distribution is narrow,the cutting point is small,and the fluidity is good.,and the applicability is strong.

High degree of automation

Using PLC/DCS automatic control system,can achieve remote control,easy to operate.

High reliability

It adopts electronic limit and mechanical limit protection devices to avoid severe vibration and destructive impact, making the operation more stable.

| Models | Main machine power (kW) |

Powder classifier power (kW) |

Fan Power (kW) |

Grinding material particle size D90 (mm) |

Moisture of grinding material | Capacity (t/h) |

| SFLM1000 | 132-185 | 4×15 | 90-132 | <10(Max15) | <3% | 3-12 |

| SFLM1200 | 220-280 | 6×15 | 185-200 | 4-14 | ||

| SFLM1300 | 315-355 | 7×15 | 200-250 | 5-16 | ||

| SFLM1500 | 355-400 | 8×15 | 280-315 | 7-18 | ||

| SFLM1700 | 450-500 | 9×15 | 315-355 | 8-22 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Models | Main machine power (kW) |

Capacity (t/h) |

| SFLM1000 | 132-185 | 3-12 |

| SFLM1200 | 220-280 | 4-14 |

| SFLM1300 | 315-355 | 5-16 |

| SFLM1500 | 355-400 | 7-18 |

| SFLM1700 | 450-500 | 8-22 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

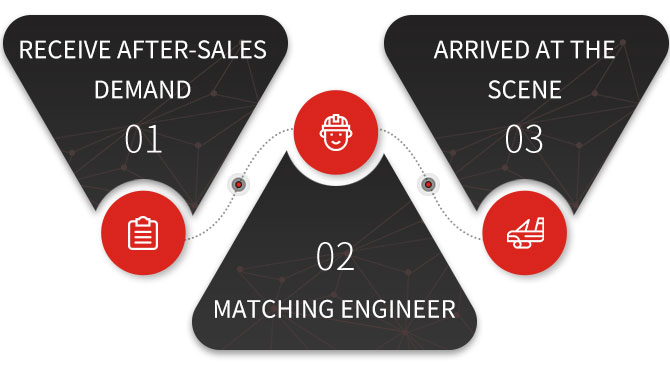

Receive after-sales demand

Matching engineer

02Arrived at the scene