- News & Events

- Blog

- Follow us

Application fields: metallurgy, chemical, building materials, electricity, transportation and other departments.

Made in China

Two weeks delivery, custom cycle, please consult

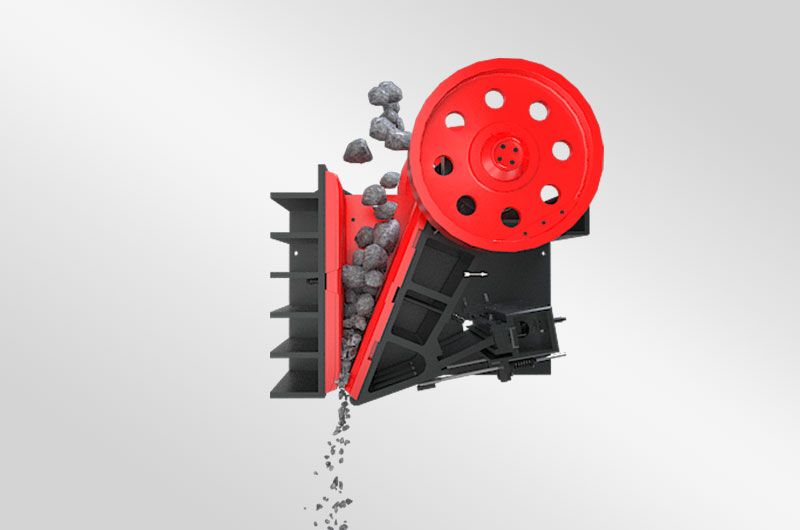

Jaw crusher is one kind of the best-selling crusher machine for stones and ores. Due to its high performance and competitive price, it is widely used for processing granite, limestone, quarry stones, gravel, basalt, aggregate, gold ore, iron ore, concrete, etc.

With the unique structure and wide throughput range, jaw crusher can be used for primary and fine crushing of over 120 kinds of stones and ores in mining, quarry, construction and other fields.

In the process of breaking huge stones into small stones, the first crusher is usually the ' main ' crusher, and the longest and most solid crusher is the jaw crusher. When feeding the jaw crusher, the material is poured into the crushing chamber containing the jaw teeth from the top inlet. The jaw teeth top the material to the wall with great force and break it into smaller stones.

pebbles, granite, basalt, limestone, quartzite, construction waste, iron ore, gold ore, etc.

Finished product specification: 10-350 (unit: mm) Processing materials:

Unique Flywheel Design : Reduce vibration effectively, Machine work is stable.

Large Crushing Ratio : low suspension motion mechanism leads to greater crushing ratio.

Easy To Maintain : Application of high wear-resisting toothed plate, long maintenance period, and cost-saving.

Low Failure Rate : Reliable performance, optimized design, the low failure rate.

We are a professional crusher manufacturer, self-produced and sold. factory price, fast delivery.

Our services are spread all over the world. We pursue high-quality service. Free training for customer-tailored solutions. Our professional after-sales team is always ready to provide you with fast and efficient service.

24-hour online customer service is at your service. If you have any questions, please click on the online service on the right to contact us! We will provide you with one-on-one professional services!

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Feeding opening size L×W(mm) | Adjustment range of discharge port(mm) | Capacity(t/h) | Power(KW) | Dimensions L×W×H(mm) |

| CJ96 | 480 | 930×580 | 60-175 | 105-390 | 4P 90 | 2850×2270×1950 |

| CJ106 | 560 | 1060×700 | 70-200 | 150-500 | 4P 110 | 3280×2580×2400 |

| CJ120 | 700 | 1200×870 | 70-200 | 175-610 | 4P 160 | 3700×2790×2950 |

| CJ125 | 760 | 1250×950 | 100-250 | 270-831 | 4P 160 | 4230×2780×2960 |

| CJ150 | 960 | 1400×1200 | 125-250 | 340-880 | 4P 200 | 5030×3440×3970 |

| CJ160 | 960 | 1600×1200 | 150-300 | 430-1145 | 4P 250 | 5780×3460×3580 |

| CJ200 | 1200 | 2000×1500 | 175-300 | 630-1435 | 6P 400 | 6600×4030×4400 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Rotor(mm) | The Maximum Feeding Size(mm) | Capacity(t/h) | Motor power(kw) | Overall dimension(L×W×H)(mm) | Weight(kg) | |

| -150MPa | -350MPa | ||||||

| HD1110 | Φ1040×1000 | 400 | 200 | 90~190 | 4P 90-132 | 3000×2360×2385 | 15875 |

| HD1315 | Φ1300×1500 | 700 | 300 | 180~280 | 4P 200-270 | 3735×3156×3055 | 29600 |

| HD1520 | Φ1500×2000 | 1000 | 400 | 350~500 | 4P 400-500 | 4310×3330×3660 | 42000 |

| HD1625 | Φ1650×2500 | 1300 | 500 | 500~670 | 4P 500-670 | 5540×4330×4600 | 66000 |

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Capacity(t/h) |

| CJ96 | 480 | 105-390 |

| CJ106 | 560 | 150-500 |

| CJ120 | 700 | 175-610 |

| CJ125 | 760 | 270-831 |

| CJ150 | 960 | 340-880 |

| CJ160 | 960 | 430-1145 |

| CJ200 | 1200 | 630-1435 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Rotor (mm) |

Discharging (mm) |

Capacity (t/h) |

|

| -150MPa | -350MPa | ||

| Φ1040×1000 | 400 | 200 | 90-190 |

| Φ1300×1500 | 700 | 300 | 180~280 |

| Φ1500×2000 | 1000 | 400 | 350~500 |

| Φ1650×2500 | 1300 | 500 | 500~670 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene