- News & Events

- Blog

- Follow us

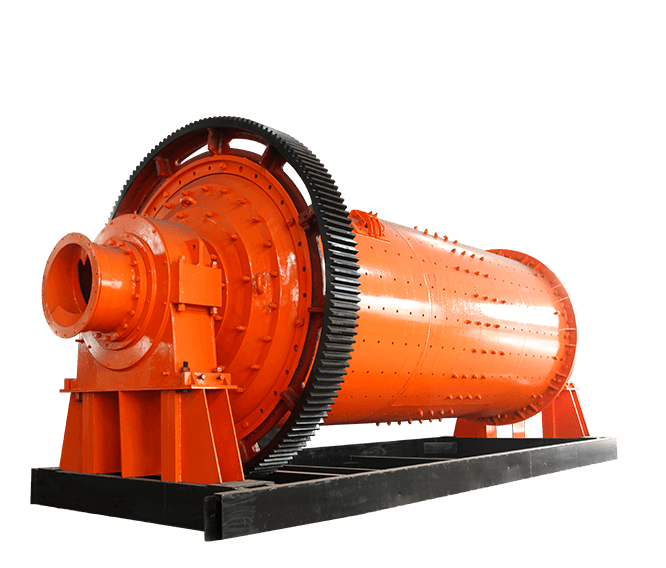

Application fields: Cement, silicate products, new building materials, refractory materials, glass ceramics and other production industries.

Made in China

Two weeks delivery, custom cycle, please consult

The slag mill is the key equipment for re-grinding after the slag is pre-pulverized. It is mainly used in the slag powder production industry and cement grinding stations.

Copper ore, hematite, slag, molybdenum ore, gold ore, iron ore, water slag, slag, etc.

1. The slag grinding adopts high-fine sieving grinding technology, double-layer compartments with special structure, active lining and grinding tail discharging devices to meet the customer's demand for grinding fineness.

2. The new internal grading liner is used inside the cylinder, and the micro-grinding body is used to carry out high-linearity ink and grinding on the material.

3. Stable performance of equipment, can greatly reduce the power consumption of integrated grinding, and save customers’ money.

4. The low energy consumption features save disposal costs but increase productivity for you.

When the slag grinding cylinder body is driven to rotate by the transmission device, the grinding body is attached to the lining surface of the inner wall of the equipment cylinder due to the action of the inertia centrifugal force and is rotated to a certain height, and then freely falls by gravity. When the grinding body crushes the material in the simplified body, the grinding body has a rising and falling circular motion in the rotating slag grinding device, causing sliding and rolling, causing grinding between the grinding body, the lining plate and the material to be ground to make the material Grinding.

| (Dia.×Length) (m) |

Speed (r/min) |

Feeding Size (mm) |

Griding Media Loading (t) |

Main Motor (KW) |

Main Reducer |

| Φ2.2×7.0 | 21.5 | <25 | 32 | 380 | ZD70 |

| Φ2.2×9.0 | 21.5 | <25 | 44 | 480 | ZD70 |

| Φ2.2×9.5 | 21.5 | <25 | 45 | 480 | ZD70 |

| Φ2.2×11 | 21.5 | <25 | 58 | 630 | ZD80 |

| Φ2.2×13 | 21.5 | <25 | 58 | 630 | ZD80 |

| Φ2.4x10 | 20.3 | <25 | 55 | 630 | ZD80 |

| Φ2.4×11 | 20.3 | <25 | 62 | 710 | MBY710 |

| Φ2.4×12 | 20.3 | <25 | 68 | 800 | MBY710 |

| Φ2.4×13 | 20.3 | <25 | 68 | 800 | MBY710 |

| Φ2.6×11 | 19.7 | <25 | 68 | 800 | MBY710 |

| Φ2.6×13 | 19.7 | <25 | 82 | 1000 | MBY800 |

| Φ3.0×9.0 | 18.2 | <25 | 78 | 1000 | MBY800 |

| Φ3.0×11 | 18.2 | <25 | 95 | 1250 | MBY800 |

| Φ3.0×12 | 18.2 | <25 | 100 | 1250 | MBY800 |

| Φ3.0×13 | 18.2 | <25 | 108 | 1400 | MBY900 |

| Φ3.2×11 | 17.8 | <25 | 110 | 1400 | MBY900 |

| Φ3.2×13 | 17.8 | <25 | 128 | 1600 | MBY1000 |

| Φ3.2×13 | 17.7 | <25 | 128 | 1600 | JS120-A |

| Φ3.2×14 | 17.8 | <25 | 138 | 1800 | MBY1000 |

| Φ3.5×11 | 17.1 | <25 | 160 | 1800 | MBY1000 |

| Φ3.5×13 | 17.3 | <25 | 175 | 2000 | MBY1000 |

| Φ3.8×12 | 17 | <25 | 175 | 2500 | JS130-C |

| Φ3.8×13 | 17 | <25 | 190 | 2500 | MBY1100 |

| Φ4.0×13 | 16.3 | <26 | 200 | 2800 | IS140-A |

| Φ4.2×11 | 15.8 | <25 | 195 | 2800 | JS140-A |

| Φ4.2x13 | 15.8 | <25 | 230 | 3150 | JS140-C |

| Φ4.2×14 | 15.6 | <25 | 252 | 3550 | JS150-B |

| Φ4.2×15 | 15.6 | <25 | 270 | 4000 | JS160-B |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| (Dia.×Length) (m) |

Speed (r/min) |

Feeding Size (mm) |

Griding Media Loading (t) |

| Φ2.2×7.0 | 21.5 | <25 | 32 |

| Φ2.2×9.0 | 21.5 | <25 | 44 |

| Φ2.2×9.5 | 21.5 | <25 | 45 |

| Φ2.2×11 | 21.5 | <25 | 58 |

| Φ2.2×13 | 21.5 | <25 | 58 |

| Φ2.4x10 | 20.3 | <25 | 55 |

| Φ2.4×11 | 20.3 | <25 | 62 |

| Φ2.4×12 | 20.3 | <25 | 68 |

| Φ2.4×13 | 20.3 | <25 | 68 |

| Φ2.6×11 | 19.7 | <25 | 68 |

| Φ2.6×13 | 19.7 | <25 | 82 |

| Φ3.0×9.0 | 18.2 | <25 | 78 |

| Φ3.0×11 | 18.2 | <25 | 95 |

| Φ3.0×12 | 18.2 | <25 | 100 |

| Φ3.0×13 | 18.2 | <25 | 108 |

| Φ3.2×11 | 17.8 | <25 | 110 |

| Φ3.2×13 | 17.8 | <25 | 128 |

| Φ3.2×13 | 17.7 | <25 | 128 |

| Φ3.2×14 | 17.8 | <25 | 138 |

| Φ3.5×11 | 17.1 | <25 | 160 |

| Φ3.5×13 | 17.3 | <25 | 175 |

| Φ3.8×12 | 17 | <25 | 175 |

| Φ3.8×13 | 17 | <25 | 190 |

| Φ4.0×13 | 16.3 | <26 | 200 |

| Φ4.2×11 | 15.8 | <25 | 195 |

| Φ4.2x13 | 15.8 | <25 | 230 |

| Φ4.2×14 | 15.6 | <25 | 252 |

| Φ4.2×15 | 15.6 | <25 | 270 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene