- News & Events

- Blog

- Follow us

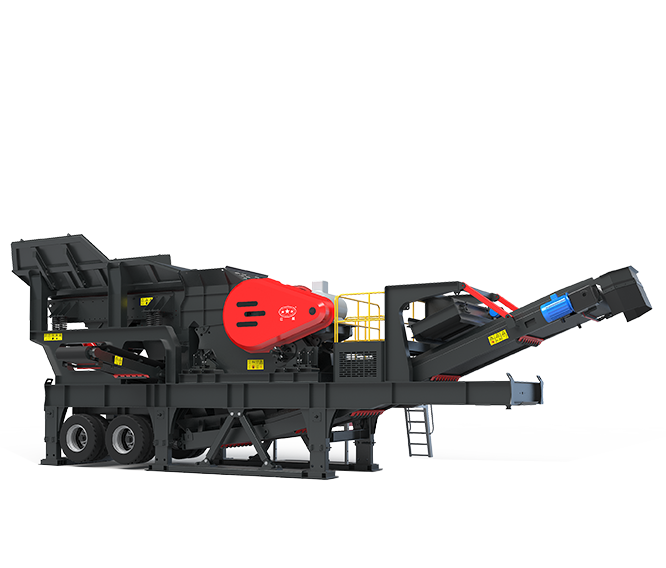

Application fields: mining, stone mining, highway (railway) construction, urban construction waste treatment, etc.

Made in China

Two weeks delivery, custom cycle, please consult

The mobile stone crusher station mainly equipped with feeder, jaw crusher and belt conveyor with the production capacity of 70~650 t/h. This machine applied for integrated operation mode, which can be operated separately, eliminates the complex site infrastructure and auxiliary facilities installation of separate components and reduces the labor consumption. It is suitable for construction waste treatment, construction waste crushing, etc.

The mobile stone crusher is the matching equipment. It can provide a variety of individualized unit configurations according to the different requirements of customers and the actual situation. It can be operated in a single machine or in multiple units, thus achieving a combination of functions such as single unit crushing, multi-unit combined classification crushing, and screening. The mobile stone crusher can be used in mines, coal mines, garbage and construction waste recycling, earth and stone works, urban infrastructure, roads or construction sites.

limestone, granite, basalt, quartz, rock, coal, iron ore, gold ore, marble, construction waste, etc.

Finished product specification: 10-350 (unit: mm) Processing materials:

1. Process simplification; High output.

2. Flexible configuration, strong adaptability.

3. The mobile stone crusher is simple in structure, easy to operate, highly-efficient and energy saving.

4. Modular, intelligent operation design, greatly reducing investment costs and increasing investment income.

One mobile stone crusher has various configuration methods so that its price is determined by the specific model number and size. However, lots of requirements can be met only by one mobile crusher, as a new-type and powerful crushing machine. Thus, it is expensive. We can offer a factory direct sale. If interested, you can contact our customer service? personnel or send emails at sinohxjq@hxjq.com

MOBLIE IMPACT CRUSHER TECHNICAL PARAMETERS

| Model | HX938F1210 | HX938FW1214 | HX1149F1315 | HX1349HD1110 | HX1349HD1315 |

| Transportation Length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

MOBLIE JAW CRUSHER TECHNICAL PARAMETERS

| Model | HX938HD80 | HX1149HD98 | HX1349HD110 | HX1349HD125 |

| Transportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 14700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dual-axial | Dual-axial | Dual-axial | Dual-axial |

| Jaw Crusher | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Model | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 200 | 250 | 270 | 400 |

| Iron Separator (Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

MOBLIE IMPACT CRUSHER TECHICAL PARAMETERS

| Model | The Maximum Feeding Size (mm) |

Production Capacity (t/h) |

| HX938F1210 | 350 | 70-130 |

| HX938FW1214 | 350 | 100-180 |

| HX1149F1315 | 500 | 130-250 |

| HX1349HD1110 | 400 | 112 |

| HX1349HD1315 | 700 | 280 |

MOBLIE JAW CRUSHER TECHNICAL PARAMETERS

| Model | Maximum Feeding Size(mm) |

Capacity(t/h) |

| HX938HD80 | 500 | 85-275 |

| HX1149HD98 | 550 | 110-350 |

| HX1349HD110 | 660 | 215-510 |

| HX1349HD125 | 800 | 280-650 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

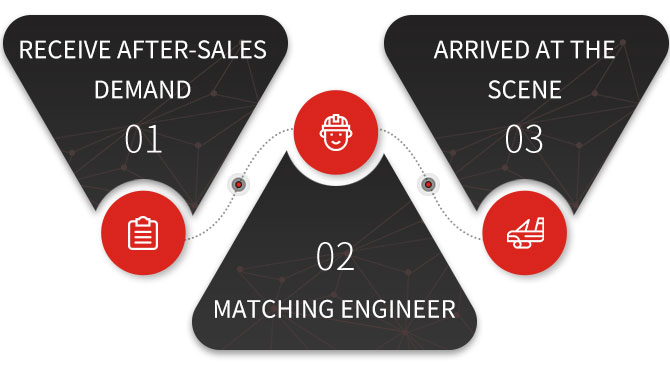

Receive after-sales demand

Matching engineer

02Arrived at the scene