- News & Events

- Blog

- Follow us

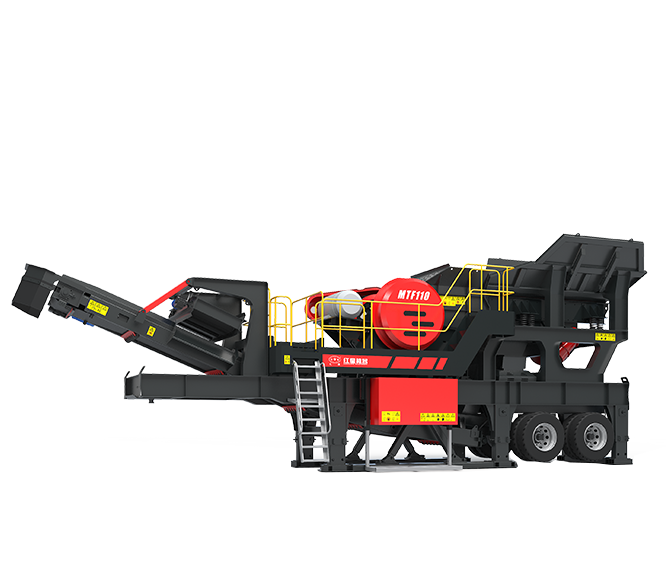

Application fields: mining, stone mining, highway (railway) construction, urban construction waste treatment, etc.

Made in China

Two weeks delivery, custom cycle, please consult

The Wheeled Mobile Crusher is optimized by the ship-shaped steel frame mechanism, hydraulic lifting, and various multi-stage combined and non-standard crushing stations. It can be customized according to customer requirements.

During the crushing process of the wheeled mobile crusher, the materials are uniformly conveyed to the HX coarse crushing tire series mobile crushing station through a bucket elevator and a feeder. After the materials are preliminarily crushed by the crusher, they form a closed-loop system with a circular vibrating screen, allowing for the circulation of materials for further crushing. The materials that meet the particle size requirements are outputted by a conveyor, thus achieving the production objectives. Alternatively, the circular vibrating screen can be removed according to actual production needs, and the materials can be directly subjected to preliminary crushing, followed by specific operations in conjunction with other crushing equipment.

cement, limestone, granite, basalt, aggregate, calcite, quartz, concrete, dolomite, bluestone, iron ore, etc.

Finished product specification: 10-350 (unit: mm) Processing materials:

1. Integrated vehicle motor and control box.

2. Energy saving and highly efficient, various configurations.

3. The crushing cavity type can be adjusted, and the application field and scope are wide.

4. Good mobility, convenient for road transportation and deep site.

The material is evenly conveyed into the crusher through the feeder. After the preliminary crusher is used for preliminary crushing, the closed circuit system is formed by the circular vibrating screen to realize the cyclic crushing of the material, and the finished material is output by the conveyor for continuous crushing operation. The wheeled mobile crusher can remove the circular vibrating screen according to the actual production needs, and realize the preliminary crushing of the material directly. It is convenient and flexible to operate with other crushing equipment.

MOBLIE IMPACT CRUSHER TECHNICAL PARAMETERS

| Model | HX938F1210 | HX938FW1214 | HX1149F1315 | HX1349HD1110 | HX1349HD1315 |

| Transportation Length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

MOBLIE JAW CRUSHER TECHNICAL PARAMETERS

| Model | HX938HD80 | HX1149HD98 | HX1349HD110 | HX1349HD125 |

| Transportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 14700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dual-axial | Dual-axial | Dual-axial | Dual-axial |

| Jaw Crusher | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Model | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 200 | 250 | 270 | 400 |

| Iron Separator (Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

| Model | HX938HD86 | HX1149HD98 | HX1349HD110 | HX1349HD125 |

| Transportation lenght(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Lenght(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial |

| Jaw Crusher | HD86 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge opening range | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m | B650×4m | B650×4m |

| Gensrt(optional) | 200KW | 250KW | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

| Model | HX938F1210 | HX938F1214 | HX1149F1315 | HX938F1110 | HX1349F1315 |

| Transportation lenght(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Lenght(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

| Model | HX3S185GYS300 | HX3S216GYS400 | HX3S216HP300 |

| Transportation length(mm) | 14500 | 15000 | 16000 |

| Transportation Width(mm) | 3000 | 3000 | 4550 |

| Transportation Height(mm) | 4400 | 4500 | 4600 |

| Maximum Length(mm) | 17000 | 16000 | 17000 |

| Maximum Width(mm) | 3400 | 3900 | 6900 |

| Maximum Height(mm) | 5800 | 6500 | 4700 |

| Weight(t) | 34.5 | 49.5 | 41 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial |

| Cone crusher | GYS300 | GYS400 | HP300 |

| Discharging belt Conveyor | B650×15M×2 | B800×15M×2 | B800×15M×2 |

| Return belt conveyor | B650×14M | B800×14M | B800×16M |

| CONveyor Belt For Final Products | B500×15M | B800×6M | B650×15M×2 |

| Under Virbrating Screen | B800×7M | B800×8M | B800×9M |

| Vibrating Screen | 3YK1854 | 3YK2160 | 3YK2160 |

MOBLIE IMPACT CRUSHER TECHICAL PARAMETERS

| Model | The Maximum Feeding Size (mm) |

Production Capacity (t/h) |

| HX938F1210 | 350 | 70-130 |

| HX938FW1214 | 350 | 100-180 |

| HX1149F1315 | 500 | 130-250 |

| HX1349HD1110 | 400 | 112 |

| HX1349HD1315 | 700 | 280 |

MOBLIE JAW CRUSHER TECHNICAL PARAMETERS

| Model | Maximum Feeding Size(mm) |

Capacity(t/h) |

| HX938HD80 | 500 | 85-275 |

| HX1149HD98 | 550 | 110-350 |

| HX1349HD110 | 660 | 215-510 |

| HX1349HD125 | 800 | 280-650 |

Model HX938HD86 and HX1149HD98

| Model | HX938HD86 | HX1149HD98 |

| Transportation lenght(mm) | 12600 | 13500 |

| Transportation Width(mm) | 2600 | 2700 |

| Transportation Height(mm) | 3870 | 4200 |

| Maximum Lenght(mm) | 12500 | 14000 |

| Maximum Width(mm) | 4100 | 4500 |

| Maximum Height(mm) | 4100 | 4900 |

| Weight(t) | 39 | 57 |

| tIRE Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD86 | HD98 |

| Maximum Feeding Size(mm) | 500 | 550 |

| Discharge opening range | 50-150 | 75-175 |

| Capacity(t/h) | 85-275 | 110-350 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m |

| Gensrt(optional) | 200KW | 250KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 |

Model HX1349HD110 and HX1349HD125

| Model | HX1349HD110 | HX1349HD125 |

| Transportation lenght(mm) | 14500 | 15200 |

| Transportation Width(mm) | 2800 | 2900 |

| Transportation Height(mm) | 4450 | 4500 |

| Maximum Lenght(mm) | 16100 | 16700 |

| Maximum Width(mm) | 5100 | 5100 |

| Maximum Height(mm) | 5000 | 5300 |

| Weight(t) | 55 | 65 |

| Tire Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD110 | HD125 |

| Maximum Feeding Size(mm) | 660 | 800 |

| Discharge opening range | 100-200 | 125-225 |

| Capacity(t/h) | 215-510 | 280-650 |

| Vibrating Feeder | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-10 | RCYD(C)-12 |

Model HX938F1210 and HX938F1214 and HX1149F1315

| Model | HX938F1210 | HX938F1214 | HX1149F1315 |

| Transportation lenght(mm) | 12000 | 12000 | 13900 |

| Transportation Width(mm) | 2550 | 2550 | 2900 |

| Transportation Height(mm) | 3900 | 3900 | 4450 |

| Maximum Lenght(mm) | 12500 | 12500 | 13900 |

| Maximum Width(mm) | 3250 | 3260 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW |

| iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 |

Model HX938F1110 and HX1349F1315

| Model | HX938F1110 | HX1349F1315 |

| Transportation lenght(mm) | 15450 | 15450 |

| Transportation Width(mm) | 2950 | 2950 |

| Transportation Height(mm) | 4500 | 4500 |

| Maximum Lenght(mm) | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3250 |

| Maximum Height(mm) | 5200 | 5200 |

| Weight(t) | 62 | 62 |

| Impact crusher | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 400 | 700 |

| Capacity(t/h) | 112 | 280 |

| Vibrating Feeder | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-12 |

| Model | HX3S185GYS300 | HX3S216GYS400 | HX3S216HP300 |

| Transportation length(mm) | 14500 | 15000 | 16000 |

| Transportation Width(mm) | 3000 | 3000 | 4550 |

| Transportation Height(mm) | 4400 | 4500 | 4600 |

| Maximum Length(mm) | 17000 | 16000 | 17000 |

| Maximum Width(mm) | 3400 | 3900 | 6900 |

| Maximum Height(mm) | 5800 | 6500 | 4700 |

| Weight(t) | 34.5 | 49.5 | 41 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial |

| Cone crusher | GYS300 | GYS400 | HP300 |

| Discharging belt Conveyor | B650×15M×2 | B800×15M×2 | B800×15M×2 |

| Return belt conveyor | B650×14M | B800×14M | B800×16M |

| CONveyor Belt For Final Products | B500×15M | B800×6M | B650×15M×2 |

| Under Virbrating Screen | B800×7M | B800×8M | B800×9M |

| Vibrating Screen | 3YK1854 | 3YK2160 | 3YK2160 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

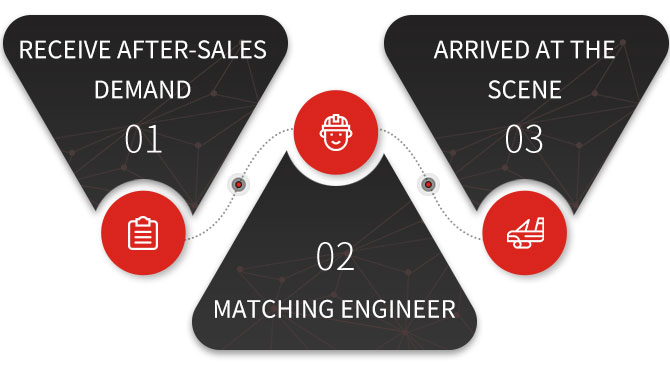

Receive after-sales demand

Matching engineer

02Arrived at the scene