- News & Events

- Blog

- Follow us

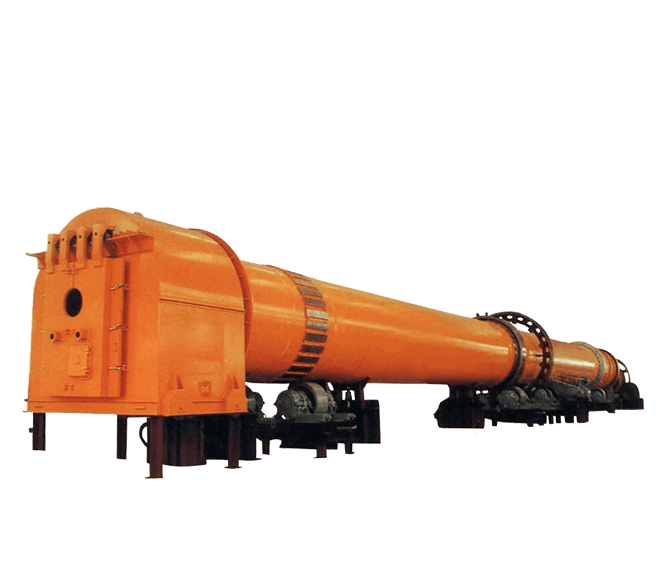

Applicable materials: limestone, cement clinker, bauxite, activated lime, aluminum hydroxide, etc.

Made in China

Two weeks delivery, custom cycle, please consult

As a kind of rotary kiln, the lime kiln, also called active lime rotary kiln, is the main equipment used to calcine active lime, consisting of the drum body, the supporting device, the supporting device with hydraulic retaining wheel, the device, the device, the device for kiln tail.

It is mainly used for magnetization roasting of iron ore in iron and steel mines in metallurgical industry; oxidizing roasting of chromium and ilmenite.

1. Effectively improving the preheating effect and high decomposition rate.

2. The Kiln lining is made from composite refractory material to reduce heat loss.

3. The simple structure; reliable operation; and convenient for the automation control.

4. The lime kiln has an advanced structure and adopts the both-ends combined sealing scales, which can decrease the possibility of air leakage.

Inside the kiln, coal powder or natural gas generates a quantity of heat, which, by the transfer of air, heats the material. At the moment, with the constant rotation of the kiln body based on the design of the slope and speed, the material rolls and advances inside the kiln periodically from the feeding end toward another end. In this period, the material has been calcined into the qualified clinker.

Service Concept: Creating value for clients; satisfying clients’ needs.

Service Target: Beyond clients’ expectation; beyond industry standards.

Service Strategy: To lower the clients’ cost by the standard, diverse, and beneficial service, to increase Hongxing’s competitiveness in brand and service.

Service Guarantee: 24h online technical people for you; if the fault hasn’t been disposed of completely, our service engineer can’t leave the actual site until we get the client’s permission.

| Design capacity (t/d) |

150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

|

| Preheater | round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre-heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

Vertical Polygon preheater |

Vertical Polygon preheater |

Vertical Polygon preheater |

|

| Rotary kiln |

Specification (m) |

Φ2.5 × 40 |

Φ2.8 × 42 |

Φ3 × 46 |

Φ3.2 × 50 |

Φ3.5 × 54 |

Φ3.6 × 56 |

Φ3.8 × 58 |

Φ4×60 Φ4.2×50 |

Φ4.3 × 58 |

Φ4.3 × 64 |

Φ4.8 × 68 |

| Effective volume (m³) |

142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/548 | 670 | 738 | 1005 | |

| Burning temperature (°C) |

1350/ 1250 |

1350/ 1250 |

1350/ 1250 |

1350/ 1250 |

1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooler | Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

|

| Fuel | Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

|

| Heat rate ( KJ/KgC3O

) |

5300/ 5000 |

5300/ 5000 |

5300/ 5000 |

5300/ 5000 |

5225 | 5225 | 5100 | 5100 | 4810 | 4810 | 4810 | |

| Design capacity (t/d) |

Specification (m) |

Burning temperature (°C) |

| 150 | Φ2.5 × 40 |

1350/ 1250 |

| 200 | Φ2.8 × 42 |

1350/ 1250 |

| 250 | Φ3 × 46 |

1350/ 1250 |

| 300 | Φ3.2 × 50 |

1350/ 1250 |

| 350 | Φ3.5 × 54 |

1350 |

| 400 | Φ3.6 × 56 |

1350 |

| 500 | Φ3.8 × 58 |

1350 |

| 600 | Φ4×60 Φ4.2×50 |

1350 |

| 750 | Φ4.3 × 58 |

1350 |

| 800 | Φ4.3 × 64 |

1350 |

| 1000 | Φ4.8 × 68 |

1350 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene