- News & Events

- Blog

- Follow us

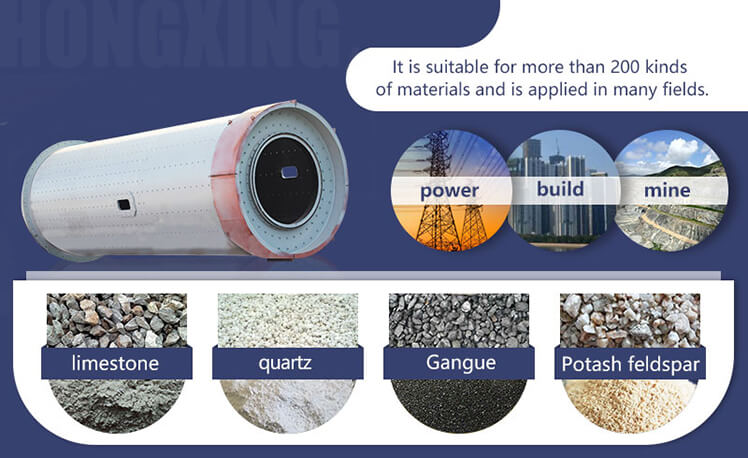

Application fields: cement, silicate products, new building materials, refractory materials, glass ceramics and other production industries.

Made in China

Two weeks delivery, custom cycle, please consult

Cement mill is mainly used for grinding various cement clinker and other materials in the building materials,metallurgy,power and chemical industries.

The cement mill is a horizontal cylindrical rotating device with external gear transmission and two bins. The material is uniformly fed into the first chamber of the mill by the feeding device through the hollow shaft of the feeding material. The chamber has stepped lining or corrugated lining, which is equipped with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel ball to a certain height and then falls, which causes heavy impact and grinding on the material. After the material reaches the rough grinding in the first bin, it enters the second bin through the single-layer partition plate. The bin is embedded with a flat liner with steel balls inside to further grind the material. The powder is discharged through the discharge raft to complete the grinding operation.

Limestone, stone powder, sand, cement clinker, bauxite, activated lime, aluminum hydroxide, etc.

Using advanced process design, the cylinder is tightly sealed to ensure dust overflow during operation.

The cylinder is cast with high-quality steel to extend the service life.

The good effect of saving energy, strong durability, low cost of grinding

The machine output can be increased by 15-20% compared with the general cement mill. the power consumption is reduced by about 10%

Compared with the same size ball mill, the mill output has been greatly improved, and it can be used for dry or wet grinding of various ores and grindable materials. The choice of the specific production process depends on the actual production needs of the customer, you can contact our online customer service, or leave a message in the message box below, your contact information and needs, such as materials, production. Or send an email to sinohxjq@hxjq.com. We will contact you as soon as possible!

| (Dia.×Length) (m) |

Speed (r/min) |

Feeding Size (mm) |

Griding Media Loading (t) |

Main Motor (KW) |

Main Reducer |

| Φ2.2×7.0 | 21.5 | <25 | 32 | 380 | ZD70 |

| Φ2.2×9.0 | 21.5 | <25 | 44 | 480 | ZD70 |

| Φ2.2×9.5 | 21.5 | <25 | 45 | 480 | ZD70 |

| Φ2.2×11 | 21.5 | <25 | 58 | 630 | ZD80 |

| Φ2.2×13 | 21.5 | <25 | 58 | 630 | ZD80 |

| Φ2.4x10 | 20.3 | <25 | 55 | 630 | ZD80 |

| Φ2.4×11 | 20.3 | <25 | 62 | 710 | MBY710 |

| Φ2.4×12 | 20.3 | <25 | 68 | 800 | MBY710 |

| Φ2.4×13 | 20.3 | <25 | 68 | 800 | MBY710 |

| Φ2.6×11 | 19.7 | <25 | 68 | 800 | MBY710 |

| Φ2.6×13 | 19.7 | <25 | 82 | 1000 | MBY800 |

| Φ3.0×9.0 | 18.2 | <25 | 78 | 1000 | MBY800 |

| Φ3.0×11 | 18.2 | <25 | 95 | 1250 | MBY800 |

| Φ3.0×12 | 18.2 | <25 | 100 | 1250 | MBY800 |

| Φ3.0×13 | 18.2 | <25 | 108 | 1400 | MBY900 |

| Φ3.2×11 | 17.8 | <25 | 110 | 1400 | MBY900 |

| Φ3.2×13 | 17.8 | <25 | 128 | 1600 | MBY1000 |

| Φ3.2×13 | 17.7 | <25 | 128 | 1600 | JS120-A |

| Φ3.2×14 | 17.8 | <25 | 138 | 1800 | MBY1000 |

| Φ3.5×11 | 17.1 | <25 | 160 | 1800 | MBY1000 |

| Φ3.5×13 | 17.3 | <25 | 175 | 2000 | MBY1000 |

| Φ3.8×12 | 17 | <25 | 175 | 2500 | JS130-C |

| Φ3.8×13 | 17 | <25 | 190 | 2500 | MBY1100 |

| Φ4.0×13 | 16.3 | <26 | 200 | 2800 | IS140-A |

| Φ4.2×11 | 15.8 | <25 | 195 | 2800 | JS140-A |

| Φ4.2x13 | 15.8 | <25 | 230 | 3150 | JS140-C |

| Φ4.2×14 | 15.6 | <25 | 252 | 3550 | JS150-B |

| Φ4.2×15 | 15.6 | <25 | 270 | 4000 | JS160-B |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| (Dia.×Length) (m) |

Speed (r/min) |

Feeding Size (mm) |

Griding Media Loading (t) |

| Φ2.2×7.0 | 21.5 | <25 | 32 |

| Φ2.2×9.0 | 21.5 | <25 | 44 |

| Φ2.2×9.5 | 21.5 | <25 | 45 |

| Φ2.2×11 | 21.5 | <25 | 58 |

| Φ2.2×13 | 21.5 | <25 | 58 |

| Φ2.4x10 | 20.3 | <25 | 55 |

| Φ2.4×11 | 20.3 | <25 | 62 |

| Φ2.4×12 | 20.3 | <25 | 68 |

| Φ2.4×13 | 20.3 | <25 | 68 |

| Φ2.6×11 | 19.7 | <25 | 68 |

| Φ2.6×13 | 19.7 | <25 | 82 |

| Φ3.0×9.0 | 18.2 | <25 | 78 |

| Φ3.0×11 | 18.2 | <25 | 95 |

| Φ3.0×12 | 18.2 | <25 | 100 |

| Φ3.0×13 | 18.2 | <25 | 108 |

| Φ3.2×11 | 17.8 | <25 | 110 |

| Φ3.2×13 | 17.8 | <25 | 128 |

| Φ3.2×13 | 17.7 | <25 | 128 |

| Φ3.2×14 | 17.8 | <25 | 138 |

| Φ3.5×11 | 17.1 | <25 | 160 |

| Φ3.5×13 | 17.3 | <25 | 175 |

| Φ3.8×12 | 17 | <25 | 175 |

| Φ3.8×13 | 17 | <25 | 190 |

| Φ4.0×13 | 16.3 | <26 | 200 |

| Φ4.2×11 | 15.8 | <25 | 195 |

| Φ4.2x13 | 15.8 | <25 | 230 |

| Φ4.2×14 | 15.6 | <25 | 252 |

| Φ4.2×15 | 15.6 | <25 | 270 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene