- News & Events

- Blog

- Follow us

Applied materials: gold ore, iron ore, copper ore, tin, tungsten, tantalum, niobium, cement clinker, pyrrhotite, hematite, etc.

Made in China

Two weeks delivery, custom cycle, please consult

The high frequency vibrating screen is referred to as a high-frequency screen, which is composed of a vibration exciter, a slurry distributor, a screen frame, a frame, a suspension spring, and a screen. It is widely used in mineral processing, coal preparation, chemistry, brick making, food, pharmaceutics, alkali, fertilizer, paper, and other industries.

Adopting the new principle design, it is a new type of high-efficiency vibrating screening machine with a screening efficiency of over 70%, small amplitude, and high screening frequency. Different from the principle of general screening equipment, the high-frequency screen uses high frequency and it can destroy the tension of the slurry surface and the high-speed oscillation of the fine material on the sieve surface, accelerate the separation of large-density useful minerals, and increase the probability of separating the material in a smaller particle size.

cement, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressing and other industries.

1. The high-frequency screen has high efficiency, small amplitude, and high screening frequency.

2. The sieve machine adopts a new principle design. It is a new structure of high-efficiency screen vibrating screening machine, generally using nylon or stainless steel sieve plates.

3. The side plate of the screen box is formed by integral bending of the steel plate, which not only improves its overall rigidity and working reliability but also makes the shape of the equipment more beautiful.

4. Reliable structure, strong excitation force, small vibration noise, being sturdy and durable, long service life, low maintenance costs.

Hongxing Mining Machinery Co., Ltd. has strong productivity and advanced technology research and development. We are committed to providing our customers with efficient service and high-quality products.

The company occupies an area of 350,000 square meters; it has 260,000 square meters of heavy industrial plants; more than 200 large and medium-sized processing and assembly equipment.

With three state-level machinery research institutes and more than 120 of employees for research & development, 10 with doctor's degrees, 30 with master's degrees and with more than 50 of state patents.

| Specification Model |

Processing capacity(t/h) |

Power (kw) |

| GPS-4 | 15-25 | 0.72 |

| GPS-5 | 20-30 | 1.1 |

| GPS-6 | 24-36 | 1.5 |

| GPS-8 | 32-48 | 2.2 |

| Specification Model |

Processing capacity (t/h) |

Power (kw) |

| GPS-4 | 15-25 | 0.72 |

| GPS-5 | 20-30 | 1.1 |

| GPS-6 | 24-36 | 1.5 |

| GPS-8 | 32-48 | 2.2 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

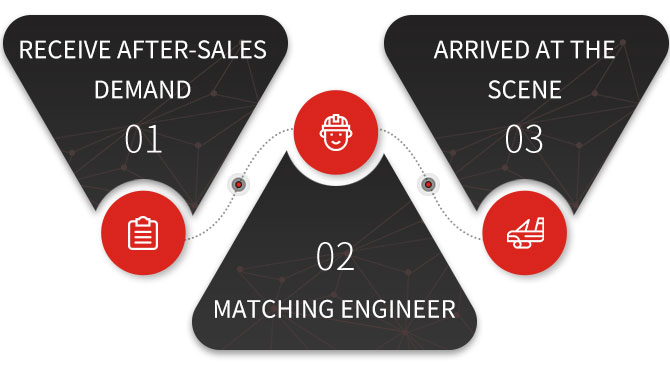

Receive after-sales demand

Matching engineer

02Arrived at the scene