- News & Events

- Blog

- Follow us

Application fields: calcium carbonate pulverization processing, gypsum powder processing, power plant desulfurization, non-metallic mineral milling, pulverized coal preparation, etc.

Made in China

Two weeks delivery, custom cycle, please consult

High strength grinding mill machine is suitable for the processing of more than 280 kinds of materials. Such as barite, limestone, ceramics, slag, which Mohs hardness is no more than 9.3, humidity is less than 6%. Suitable for non-flammable and explosive mines, metallurgy, chemical industry, building materials, and other industries.

The particle size of finished products can be adjusted in the range of 80-425 mesh (the finest 1000 mesh). Through the special device added in the machine, it can produce 30-80 mesh coarse powder.

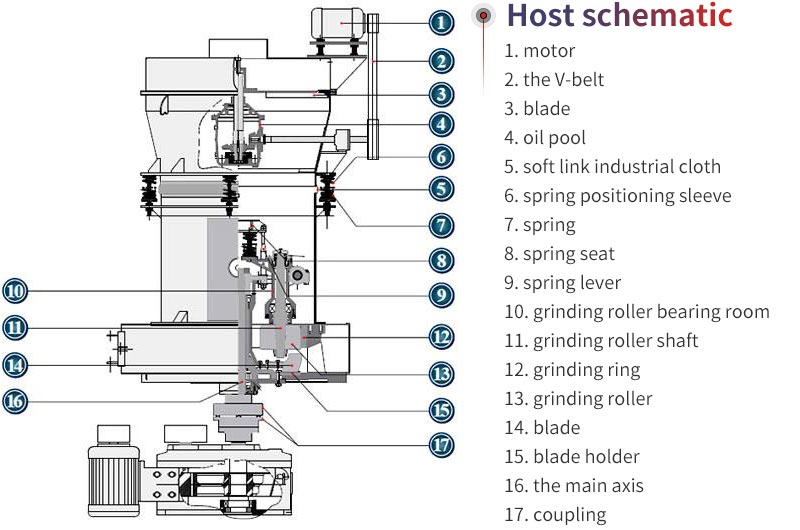

In the high strength grinding mill machine, a high-pressure spring with a pressure of 1000-1500 kg is fastened on the roller hanger. After starting work, the grinding roller rotates around the main shaft, and under the action of the high-pressure spring and the centrifugal force, it is pressed against the grinding ring, and the pressure is 1.2 times higher than that of the Raymond mill under the same dynamic condition, so the output is greatly improved. When the material to be ground enters the grinding chamber, it is shoveled by the blade and sent to the grinding roller and the grinding ring for rolling. After rolling, the powder is brought into the analysis machine along with the circulating air of the blower, and the qualified fine powder enters the cyclone powder collector as the finished product, and the large granular material falls back to the regrind.

The circulating air is returned to the blower and the above process is repeated, and the residual air is purified by the bag filter. When the wear of the grinding roller and the grinding ring reaches a certain level, the length of the high-pressure spring is adjusted to maintain a constant rolling pressure between the grinding roller and the ring, which ensures a stable output.

gypsum, quartz, dolomite, limestone, calcite, barite, ceramics, slag, etc

1. Uniform fineness of the finished powder, 99% screening rate, which is difficult for other milling equipment.

2. The transmission device adopts sealed gearbox and pulley, which makes the transmission smooth and the operation reliable

3. The important parts are made of high-quality steel, and the wear-resistant parts are made of high-performance wear-resistant materials.

4. The high-strength grinding adopts a three-dimensional structure, which has a small area and a strong set of integrity. It is a self-contained production system from block to finished powder.

In the main machine of high strength grinding, the suspension frame of grinding roller is tightened with the spring of 1000-1500kg pressure. After starting work, the grinding roller rotates around the main shaft, and under the action of high-pressure spring and centrifugal force, it rolls close to the grinding ring. When the grinding material enters the grinding chamber, it is scooped up by a shovel knife and sent to the grinding roller and ring for rolling. After rolling, the powder is brought into the analytical machine with the circulating wind of the blower. The Qualified fine powder flows into the cyclone powder collector with the air, which is the finished product, large granular materials fall back to be reground.

Our customers come from all over the world. If you are interested in our products, you can contact us immediately! Or send an email at sinohxjq@hxjq.com

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene