- News & Events

- Blog

- Follow us

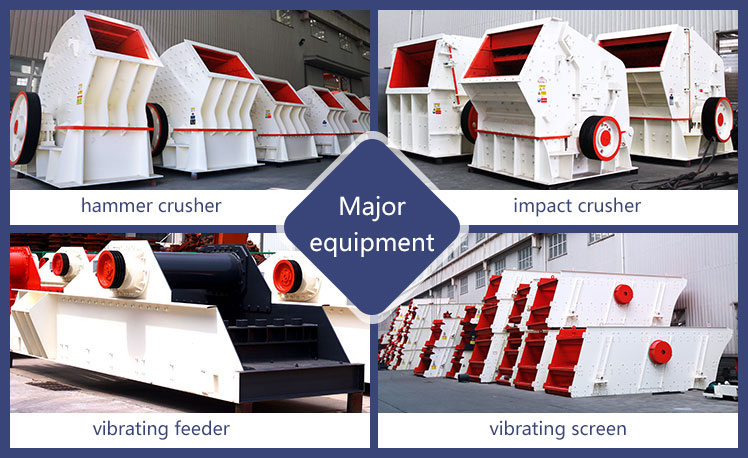

Major equipment: impact crusher, hammer crusher, vibrating screen, belt conveyor, etc

Made in China

Two weeks delivery, custom cycle, please consult

Crushing and screening equipment is composed of an impact crusher and vibrating feeder, vibrating screen, belt conveyor, etc. It is widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on

The crushing and screening can crush more than 200 kinds of rough stones such as granite, basalt, limestone, rock, concrete, aggregate, gravel, dolomite and quartz.

pebble, limestone, granite, basalt, diabase, andesite, etc.

Flexible maneuverability

Reduce the cost of transporting material

High efficiency and direct working

Better adaptability and flexible layout

We provide you with free installation service. We have a technical installation group with much experience.

After the installation, our technical people will train and assist clients about the operation on site.

After the machines have been put into production fluently, we’re ready to help you solve any difficulties.

We are available 24 hours a day, 7 days a week. Or you can leave your contact information and project requirements, such as materials, production, etc., in the message board below. We will have a one-on-one service, contact us!

| Model | Sieve Layer | Sieve Area (㎡) |

Mesh Size (mm) |

Max.Feeding Size (mm) |

Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double Amplitude (mm) |

Power (kw) |

Sieve Obliquity (°) |

Sieve Specification (mm) |

Dimensions (L×W×H) (mm) |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3530×1885×920 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3675×1885×1320 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4230×1990×920 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4375×1990×1320 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 11 | 20 | 1500×4800 | 5355×2195×1030 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 15 | 20 | 1500×4800 | 6055×2195×1740 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 18.5 | 20 | 1500×4800 | 6195×2195×2120 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6515×2555×1370 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6655×2555×1750 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6790×2555×2130 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7200×2945×1580 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7340×2945×1980 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 6 | 6P 37 | 20 | 2100×6000 | 7490×2945×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 6 | 6P 30 | 20 | 2400×6000 | 7200×3200×1580 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 6 | 6P 37 | 20 | 2400×6000 | 7340×3200×1980 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 6 | 6P 45 | 20 | 2400×6000 | 7490×3200×2380 |

| 2YK2866 | 2 | 31 | 5-100 | 200 | 70-650 | 970 | 6 | 6P 37 | 20 | 2800×5600 | 6950×3610×1790 |

| 3YK2866 | 3 | 47 | 5-100 | 200 | 80-700 | 970 | 6 | 6P 45 | 20 | 2800×5600 | 7130×3610×2270 |

| 4YK2866 | 4 | 62 | 5-100 | 200 | 90-750 | 970 | 6 | 6P 55 | 20 | 2800×5600 | 7300×3610×2750 |

| 2YK2873 | 2 | 39.2 | 5-100 | 200 | 70-680 | 970 | 6 | 6P 37 | 20 | 2800×6500 | 7850×3587×1790 |

| 3YK2873 | 3 | 58.8 | 5-100 | 200 | 80-720 | 970 | 6 | 6P 45 | 20 | 2800×6500 | 8025×3587×2270 |

| 4YK2873 | 4 | 58.8 | 5-100 | 200 | 90-950 | 970 | 6 | 6P 55 | 20 | 2800×6500 | 8200×3587×2750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sieve Layer | Sieve Area (㎡) |

Processing capacity (m³/h) |

| 2YK1230 | 2 | 7.2 | 12-78 |

| 3YK1230 | 3 | 10.8 | 13-80 |

| 2YK1237 | 2 | 8.88 | 15-86 |

| 3YK1237 | 3 | 13.32 | 16-90 |

| 2YK1548 | 2 | 14.4 | 22.5-162 |

| 3YK1548 | 3 | 21.6 | 22.5-162 |

| 4YK1548 | 4 | 28.8 | 22.5-162 |

| 2YK1854 | 2 | 19.44 | 32-312 |

| 3YK1854 | 3 | 29.16 | 32-312 |

| 4YK1854 | 4 | 38.88 | 32-336 |

| 2YK2160 | 2 | 25.2 | 50-475 |

| 3YK2160 | 3 | 37.8 | 50-475 |

| 4YK2160 | 4 | 50.4 | 50-497 |

| 2YK2460 | 2 | 28.8 | 65-550 |

| 3YK2460 | 3 | 43.2 | 70-620 |

| 4YK2460 | 4 | 57.6 | 80-680 |

| 2YK2866 | 2 | 31 | 70-650 |

| 3YK2866 | 3 | 47 | 80-700 |

| 4YK2866 | 4 | 62 | 90-750 |

| 2YK2873 | 2 | 39.2 | 70-680 |

| 3YK2873 | 3 | 58.8 | 80-720 |

| 4YK2873 | 4 | 58.8 | 90-950 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene